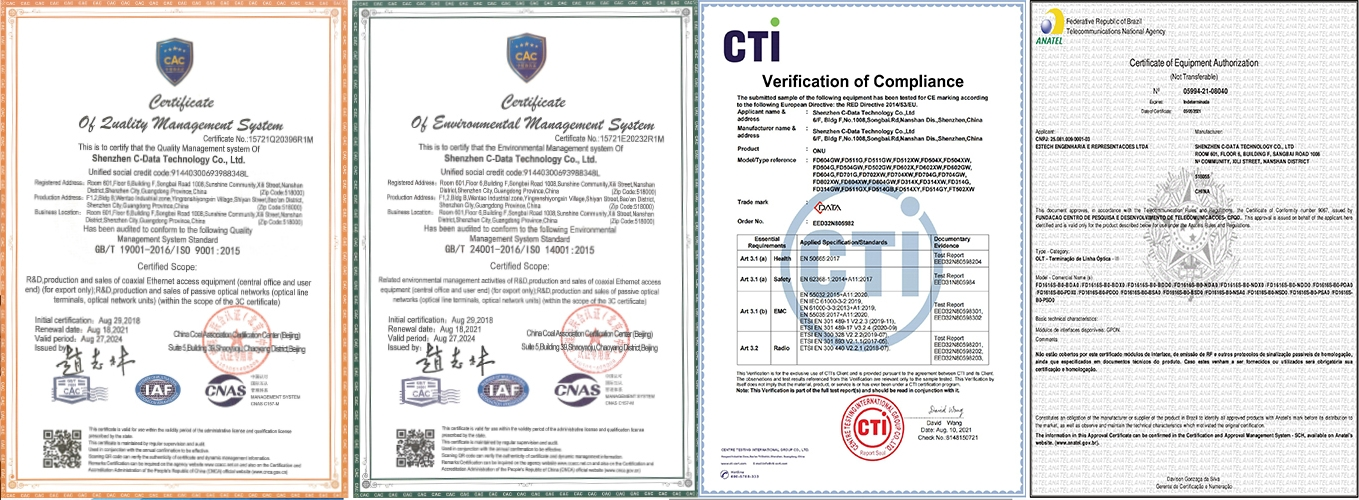

Committed to the highest industry standards, C-Data ensures quality through ISO 9001 and ISO 14001 compliance. These certifications demonstrate our dedication to delivering products that meet or exceed customer expectations, with a focus on environmental sustainability.

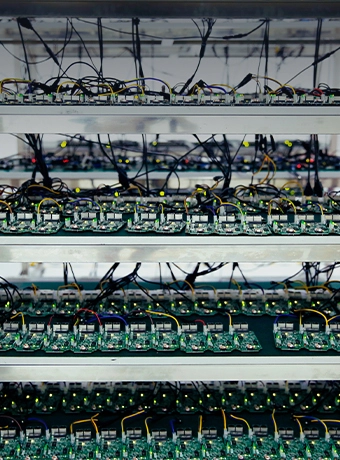

Leveraging advanced testing methods, automated processes, and thorough quality checks,

C-Data is dedicated to continuous improvement in production capacity and ensuring high-quality manufacturing.

Our steadfast dedication ensures that our products consistently exceed global industry standards and technological benchmarks.

Automated systems drive a 60% boost in efficiency at C-Data. Our ongoing optimization efforts ensure stability and efficiency, reflected in:

AOI Test Pass Rate ≥ 99.5%

FQC Sampling Qualification Rate ≥ 99.8%

FQC Batch Qualification Rate ≥ 97%

Capacity: 1,000,000 pcs/month

Integration of first piece inspection, manual visual inspection, AOI automated optical inspection, and ICT online testing.

Inspect the soldering and assembly quality of the assembled PCB board, record the FQC inspection record at the QA station, including the inspection results and faults that need correction, to ensure the delivery of high-quality PCBA.

Detailed SOP training and documentation guarantee technical excellence and a focus to quality. Following strict standards in IPQC and sampling standards elevated reliability.

DIP Batch Qualification Rate ≥ 97.00%

DIP Sampling Qualification Rate ≥ 99.50%

C-Data's automated firmware burning and software loading not only ensure accuracy but also provide highly customized services through an agile and efficient manufacturing process.

Utilizing 40 suits of wireless network tester & RF shielding box, simulating real-world wireless access environments, calibrating RF frequencies, identifying and resolving potential issues related to connectivity, security, and performance, ensuring excellent user experience.

Double verification, the BOB multi-channel automated testing system and manual recalibration, ensures modules meet specified power levels. Regular reviews and updates of procedures contribute to achieving accurate and reliable signal transmission and reception.

Covering functional testing, assembly, packaging, and final inspections for various terminal products.

Product Test Pass Rate ≥ 99.0%

OQC Sampling Qualification Rate ≥ 99.90%

Shipment Batch Qualification Rate ≥ 98.7%

Reliability testing includes vibration, aging, redundancy, ensuring uninterrupted service provision, stability, and efficiency in network access.

Comprehensive inspection of terminal and data center products covering functional testing, appearance checks, dimension measurements, reliability testing, maintaining detailed and uniquely traceable documentary.

Product Test Pass Rate ≥ 99.9%

OQC Sampling Qualification Rate ≥ 99.90%

Shipment Batch Qualification Rate ≥ 99.99%

C-Data's Research and Development Simulation Laboratory, based on the specific needs of project customers and to promote research and development innovation, can simulate and reproduce network access environments worldwide. This facility not only provides flexible environments for data transmission testing but also specializes in customized solutions and adapting products to meet unique needs.

Overall Consistency Test

Appearance and Structure Test

Access Network Test

Hardware Performance Test

Software Test

Environmental Reliability Test

Interface Performance Test

Network Security Test

Device Aging Test

support@cdatatec.com

second response within 24 hours

third response within 48 hours

fourth response within 5 days

C-Data will continue to adhere to timely, high-quality delivery standards, continually optimize costs for materials and equipment,

and provide competitive products and solutions for our customers.